Categories

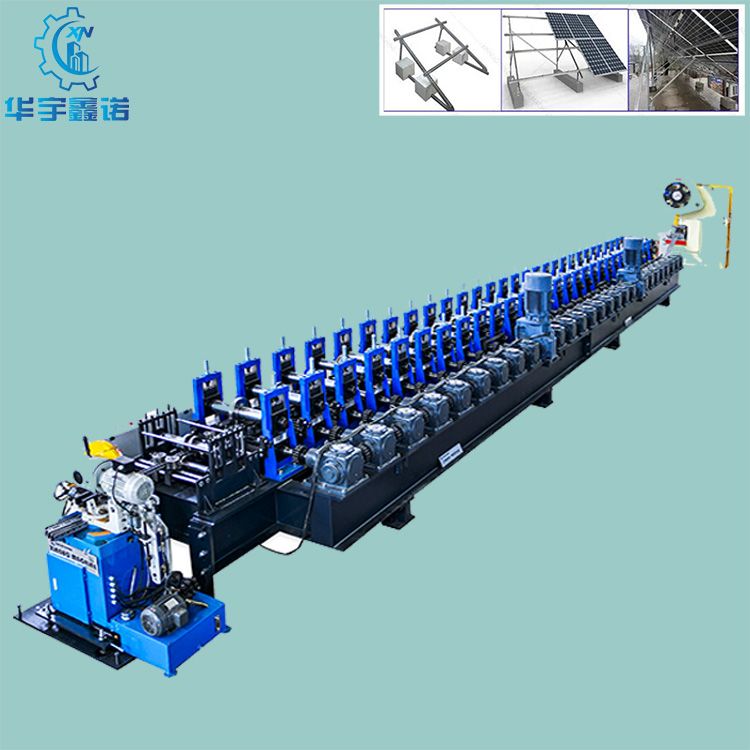

Solar strut Channel Roll Forming Machine

Product Attributes :

The above whole production line including :one set of 5 tons manual decoiler,one set of roll forming machine,one set of manual product rack.

Product Description

| Roll forming machine | Feeding device | Platform + guiding bar, with pinching roller | |

| Steel plate welded platform to carry the sheet and feed into roll forming system | |||

| Feeding width is adjustable with the handle wheels | |||

| Rolling shaft | Shaft material:45# STEEL | ||

| Shaft diameter: 80 mm | |||

| Heated treatment and quenched +cylindrical grinding+polishing+CNC machining | |||

| Roller | Gr15 | ||

| Forging+CNC machining two times,Hard Chromed treatment coated 0.05mm,Anti-corrosion,Heat treatment Polishing | |||

| Improve the hardness and prevent abrasion. Hardness Increases Extend roller lifetime . Better to protect the plate |

|||

| Rolling station | 18 rolling stations | ||

| Max forming speed | 0-45 m/min | ||

| Side wall | Independent archway,high-precision wire cutting, milling machine machining. | ||

| Sidewall Connect Bar | Diameter:30mm,Cast steel+Boiled black+High quality | ||

| Machine basic frame | 400# H steel welded,The highest standard of China's best steel brand: LAIGANG. | ||

| Main motor power | 11 kw | ||

| Rolling spacer | Anti rusty treatment | ||

| Pull rod | Anti rusty treatment | ||

| Transmission | Gear box transmission,Faster and more stable. | ||

Online Inquiry